Precision in Motion: How W-ROBOT Powers the Next Generation of Intelligent Manufacturing

2025-10-29Empowering Global Automation: W-Robot’s Drive & Control Actuator Solutions

2025-10-31In the era of smart manufacturing, automation is no longer about speed alone—it’s about flexibility, safety, and precision.

As factories evolve into intelligent ecosystems, collaborative robots (cobots) have emerged as key players enabling humans and machines to work hand in hand.

But at the heart of every successful cobot lies one crucial component — the gripper.

It’s the element that connects intelligence to the real world, translating algorithms into action.

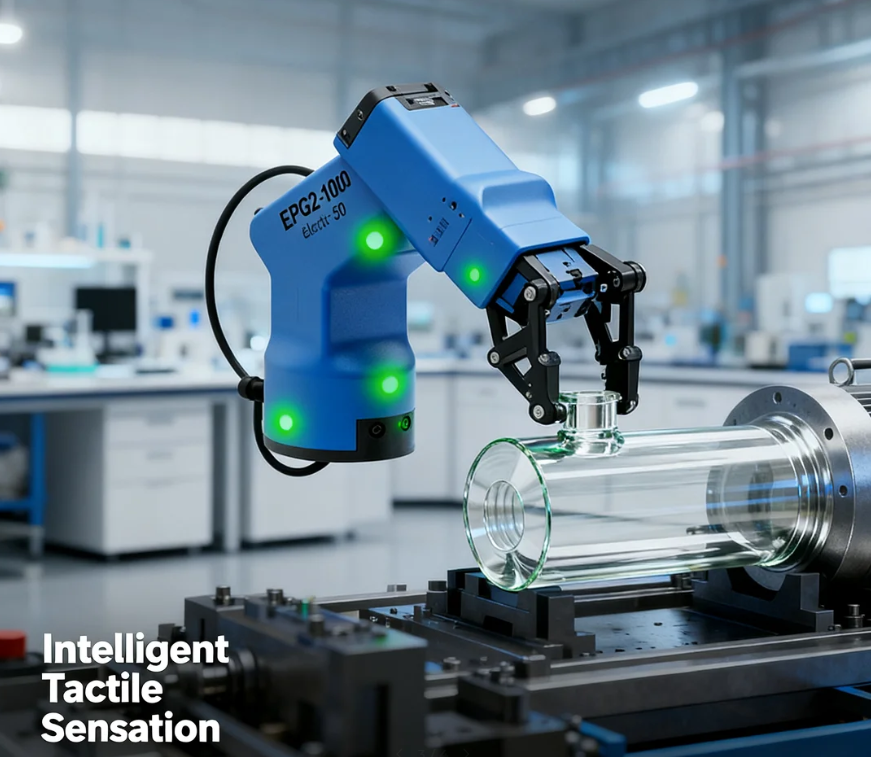

And this is where W-ROBOT’s EPG2-100-50 Collaborative Electric Gripper takes the stage — a symbol of precision, safety, and soft power in modern automation.

1. Global Trend: The Era of Collaborative Intelligence

The collaborative robot market has grown at over 20% annually over the past decade, driven by the rising need for flexible automation in electronics, automotive, life sciences, and new energy industries.

However, while control systems and vision sensors have evolved rapidly, traditional end-effectors have lagged behind — often rigid, noisy, and difficult to control.

W-ROBOT identified this pain point and set out to develop a new generation of smart, sensitive, and servo-controlled grippers capable of mimicking the dexterity of a human hand.

The result is EPG2-100-50, a lightweight yet powerful collaborative gripper designed to enhance the efficiency, safety, and intelligence of robotic systems across industries.

2. Product Overview: Compact Design Meets Intelligent Control

The EPG2-100-50 is an electrically driven, high-precision collaborative gripper developed specifically for cobots and light-duty automation systems.

It combines powerful servo actuation with a compact structure, offering smooth, programmable gripping control across a wide range of applications.

| Technical Specifications | Details |

|---|---|

| Gripping Stroke | 50 mm |

| Maximum Gripping Force | 100 N |

| Positioning Accuracy | ±0.02 mm |

| Communication Interfaces | Modbus RTU / I/O / EtherCAT |

| Protection Level | IP40 |

| Weight | 1.1 kg |

Its modular design ensures full compatibility with leading collaborative robot brands — UR, Doosan, Aubo, Fanuc, and more.

Plug-and-play integration, quiet operation, and precise feedback make EPG2-100-50 the ideal end-effector for assembly, testing, packaging, and laboratory automation.

3. Key Technical Advantages

① Servo-Driven Precision

Powered by an integrated servo controller, the EPG2-100-50 enables real-time feedback and closed-loop control.

It maintains a perfect balance between gripping strength and sensitivity — firm enough to lift metal parts, gentle enough to hold delicate components.

② Fully Programmable Motion

The gripper’s parameters, including force, speed, and stroke, are completely adjustable through software or PLC.

This allows users to tailor motion to different materials — from fragile glass lenses to metallic housings — ensuring optimal grip without damage.

③ Built-In Safety & Compliance

The system includes collision detection and force-limiting algorithms, meeting ISO 10218 and TS 15066 collaborative safety standards.

When unexpected contact occurs, the gripper automatically stops or opens, ensuring safe operation around human workers.

④ Smart Communication Interface

Equipped with multiple communication options (Modbus RTU, I/O, EtherCAT), the gripper easily integrates into existing automation systems.

Users can monitor performance, torque, and temperature in real time, simplifying preventive maintenance.

⑤ Lightweight & Durable Structure

Machined from high-strength aluminum alloy, the EPG2-100-50 features a seamless, dust-resistant enclosure and an elegant, compact form.

The total weight of just 1.1 kg ensures that cobots maintain agility while improving payload capacity.

4. Application Scenarios: Designed for Every Industry

Electronics Manufacturing

Ideal for precise handling of PCB boards, micro-components, and camera modules.

EPG2-100-50 ensures stable gripping and prevents static or mechanical damage to delicate parts.

Medical & Laboratory Automation

In laboratory sample transfer and pharmaceutical packaging, the gripper’s adjustable force guarantees hygienic, damage-free manipulation of sensitive materials.

New Energy & Green Tech

Used in lithium battery modules, solar panel assembly, and power storage production lines, the gripper provides stable handling in high-frequency, long-cycle applications.

Education & Research

Compact, safe, and easy to program, EPG2-100-50 is widely used in robotics research and STEM education programs as a benchmark tool for collaborative robot study.

🔗 Learn more about W-ROBOT’s automation solutions: www.w-robot.com

5. Comparison: Beyond Traditional Grippers

| Feature | Traditional Pneumatic Gripper | EPG2-100-50 Electric Gripper |

|---|---|---|

| Drive Mode | Pneumatic | Servo-electric |

| Control | Air pressure dependent | Fully programmable |

| Force Adjustment | Manual or fixed | Digital control via software |

| Noise | High (> 60 dB) | Low (< 40 dB) |

| Maintenance | Requires air supply | Maintenance-free |

| Safety | No collision detection | Built-in force limitation |

| Integration | Complex wiring | Plug-and-play |

EPG2-100-50 doesn’t just replace pneumatic systems — it transforms how engineers think about gripping precision and human-robot collaboration.

6. Global Customer Feedback

“We replaced pneumatic grippers with W-ROBOT’s EPG2-100-50 on our electronics line.

The installation was seamless, control is smoother, and energy consumption dropped by 30%.”

— Vietnam Electronics Manufacturer

“This gripper delivers human-like touch sensitivity with the reliability of industrial robotics.

Our cobots can now handle delicate parts with confidence.”

— Automation Integrator, Germany

Real results from global users highlight one truth: W-ROBOT’s innovation turns automation into intelligent craftsmanship.

7. Worldwide Presence: From China to the World

The EPG2-100-50 is part of W-ROBOT’s broader vision of “Global Intelligent Motion.”

The company is actively expanding its presence across Southeast Asia, the Middle East, and Europe, building strong partnerships with distributors and local service centers.

Through continuous technological upgrades, localized service, and reliable delivery, W-ROBOT empowers global manufacturers to transition toward smarter, safer, and more efficient production systems.

8. Why Choose W-ROBOT?

- Comprehensive Motion Solutions — from linear modules and electric actuators to collaborative grippers

- High-precision manufacturing with strict quality standards

- Flexible customization to meet industry-specific requirements

- Global service and support ensuring rapid response and localized expertise

W-ROBOT is more than a component supplier — it’s a motion-control partner committed to redefining the future of automation.

9. Conclusion: Smart Touch, Smarter Manufacturing

With EPG2-100-50, W-ROBOT brings the art of precision gripping to the next level.

It represents the perfect synergy of technology and sensitivity — enabling robots not only to move, but to feel.

As the world moves toward human-centric automation, W-ROBOT will continue to push boundaries, delivering advanced motion control solutions that empower global industries.