How to Build a Multi-Axis System with W-ROBOT Linear Modules in 5 Practical Steps

2025-12-16Why 3C Electronics Lines Prefer Fully-Enclosed Ball Screw Modules

2025-12-181. Start with Motion and Environment, Not Price

Before you ask for linear module price, you need a real spec, not “600 mm stroke, best price please”.

Write one sentence per axis:

“Move ___ kg over ___ mm in ___ seconds, with ±___ mm repeatability, in a ___ environment.”

From this, extract:

- Stroke length (X/Y/Z)

- Total moving mass (tooling, workpiece, cable carrier, maybe a robot gripper or electric cylinder)

- Required speed and acceleration

- Precision / repeatability target

- Environment (clean lab, dusty workshop, oil mist, chemicals, cleanroom etc.)

Only with that in hand does how to choose linear module become a technical decision instead of a price war.

👉 If you want an internal guide on defining motion specs, you can link to a piece like

Related: How to Choose Linear Modules for Automation (anchor: linear module for automation).

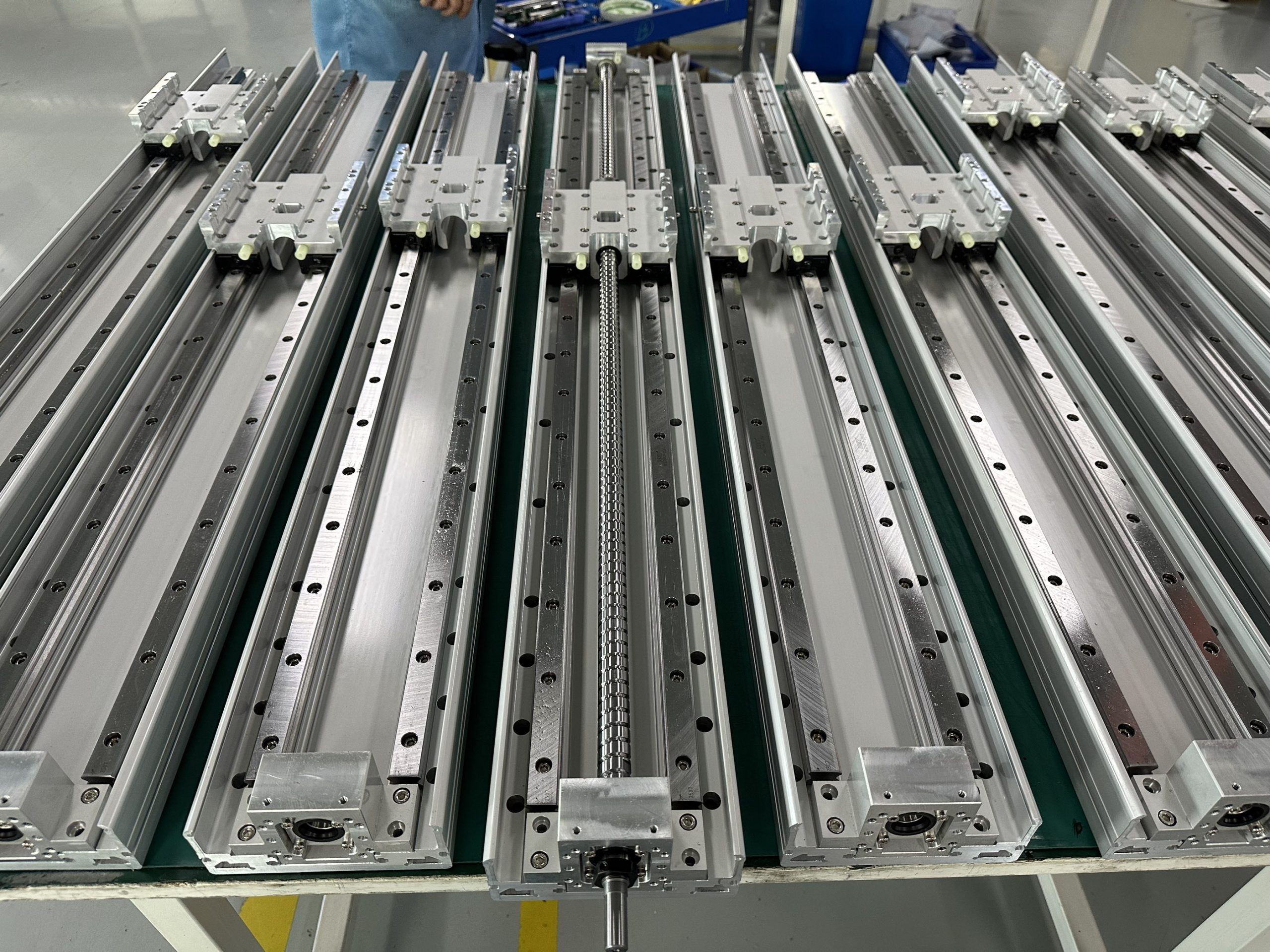

2. Check the Mechanical Stack: Guides, Screws, Belts, Structure

A modern linear module is a stack of components:

- Linear guide rail / lm guide

- Drive (screw, belt, or linear motor)

- Housing/profile, support bearing, end blocks

- Motor mount and coupling

If any of these are weak, it doesn’t matter how attractive the quote is.

2.1 Ball screw drive vs timing belt drive

Ask each supplier to explain their product families:

- Ball screw drive

- High precision, high stiffness, good for Z and short/medium strokes

- Typical for linear module for inspection machine, linear actuator for medical device automation, small XYZ linear module platform

- Timing belt drive

- Long stroke, high speed, lower moving mass

- Ideal for transfer axes, 2-axis gantry stage, large multi-axis linear actuator systems

If a supplier pushes one solution for everything, or can’t clearly explain when to use screw vs belt, that’s a warning sign.

2.2 Linear motor vs ball screw

For premium equipment—linear module for semiconductor equipment, high-speed linear module for 3C electronics, advanced AOI—ask specifically about linear motor vs ball screw:

- Linear motor: best dynamics and smoothness, but demanding on frame stiffness and budget.

- Ball screw: robust, cost-effective, easier to tune.

A serious linear module factory will tell you honestly if they mainly focus on screw/belt and partner out linear motor work.

3. Protection Level: Open, Dustproof, Cleanroom, or IP-Rated?

Not every linear module from China is designed for the same battlefield.

3.1 Match protection to real conditions

Typical levels:

- Open module

- Exposed ball screw and rails

- Fine for dry, clean environments inside cabinets

- Dustproof linear module

- Basic covers or bellows

- Suitable for packaging dust, light chips, normal workshops

- Fully enclosed linear module

- Screw and lm guide completely covered by metal strips or seals

- Used in PV glass lines, machining cells, and linear actuator for battery production line where debris is everywhere

- Cleanroom linear module / IP rated linear actuator (IP防护等级线性执行器)

- Special seals, low-outgassing lubricants

- For medical analyzers, semiconductor tools, and lab automation

Good questions to ask:

- “Which series do you recommend as a cleanroom linear module?”

- “How do you design a fully enclosed linear module for slurry or glass powder?”

- “Can you certify an IP rated linear actuator for splash or washdown zones?”

👉 Internally,你可以在文中链接到某个解决方案页,例如:

Related: Dustproof & Fully Enclosed Linear Modules for PV and Battery Lines(锚文本里使用 linear module for photovoltaic production line)。

4. System Capability: From Single Axis to Multi-Axis Linear Actuator

You’re almost never buying one axis in isolation. Real machines need coordinated motion.

4.1 Ask about multi-axis experience

Probe whether the supplier can support:

- XYZ linear module platform for small cells and inspection

- 2-axis gantry stage over conveyors or worktables

- 3-axis linear motion system for assembly, dispensing, screwdriving

And in specific industries:

- Linear module for 3C electronics – phone, tablet, wearable assembly

- Linear module for photovoltaic production line – glass handling, stringing, lamination

- Linear actuator for battery production line – electrode, cell, module handling

- Linear module for semiconductor equipment – wafer, FPC, device positioning

Ask for real reference projects or sample layouts. A supplier that regularly builds gantries and multi-axis linear actuator systems is much safer than someone who only ever ships single axes in cartons.

4.2 Combining axes and end effectors

Check how their modules behave when loaded with:

- A robot gripper for pick & place

- An electric cylinder acting as a vertical press

- Additional rotary axes on the carriage

This is where support bearings, couplings, and profile stiffness get stress-tested for real.

👉 这里可以增加一个内链,引导读者:

Related: How to Build a Multi-Axis System with W-ROBOT Linear Modules(锚文本:multi-axis linear actuator)。

5. Motors, Drivers and Motion Controller: The “Brain” of the System

Great mechanics can still fail if the motion stack is weak.

5.1 Servo motor linear module vs stepper motor linear module

Clarify what the supplier supports:

- Servo motor linear module

- For high speed, variable loads, better tuning and diagnostics

- Stepper motor linear module

- For simpler, cost-sensitive axes with modest performance needs

For compact cells, ask about an integrated motor and driver option:

- Fewer cables, easier wiring

- Cleaner layout for modular linear module for automation units

5.2 Motion controller and software

Ask how they integrate with your control world:

- Do they offer a basic motion controller for 1–4 axes?

- Can their drives talk EtherCAT / Profinet / Modbus / CANopen?

- Do they have sample programs for linear actuator for pick and place or scanning with a linear module for inspection machine?

A supplier who understands tuning, homing, and troubleshooting linear actuator issues will save your engineering team many late nights.

6. Components, Manufacturing and QC: What’s Behind the Brand?

Two suppliers may both say “C7 ball screw, 15 µm repeatability”, yet perform very differently.

6.1 Dig into the component level

Ask clearly:

- Which brands of ball screw and lm guide / linear guide rail do you use?

- Can you offer upgraded options (e.g. better bearings, different coupling, improved support bearing sets) for critical axes?

- How do you machine mounting surfaces and align rails and screws?

A real linear module factory will have:

- CNC machining centers and grinding for key parts

- Assembly jigs for parallelism and perpendicularity

- Test rigs to check smooth motion over full stroke length

6.2 Quality system, documentation and traceability

For each series, ask for:

- Drawings, load/moment curves, speed vs stroke charts

- Mounting flatness requirements and lubrication intervals

- Optional test reports for positioning and backlash

And for long-term OEM relationships:

- Serial or batch numbers on every unit

- Ability to act as your OEM linear module partner with stable designs

- Clear change-management for design or component updates

7. Cost, Lifecycle and Supplier Type: Looking Beyond Linear Module Price

Price matters—but not in isolation.

7.1 Total cost, not just unit cost

When you compare linear module price between Chinese suppliers, factor in:

- Freight, duty, packaging and insurance

- Your own design and integration effort

- Tuning, commissioning and future maintenance time

- Expected lifetime vs servo linear actuator cost or stepper-based alternatives

Sometimes a slightly higher quote from a mature linear actuator supplier with good documentation and support is cheaper than a rock-bottom offer that forces you to debug everything yourself.

7.2 Custom linear actuator and platform strategy

If you will repeat the same machine design:

- Ask if they can build a custom linear actuator variant just for your platform.

- Discuss volumes, shared forecasts, and price-breaks over time.

- Check how flexible they are as an OEM linear module partner—branding, labeling, tailored options.

For long-running platforms, building a tight relationship with one or two strong Chinese linear module manufacturers pays off far more than constantly chasing the absolute lowest quote.

👉 这一段可以自然加一个站内引导:

Related: Why Work with a Dedicated Linear Module Manufacturer Instead of a Trader(锚文本里包含 linear actuator supplier / linear module manufacturer)。

8. Sampling, Pilot Runs and Troubleshooting

Don’t jump from catalog PDF to container-size orders. Use a staged approach.

8.1 Sample and abuse a few units

For each shortlisted series:

- Order 2–3 units in the exact configuration (stroke, motor, protection) you want.

- Mount them in a real frame, at real load.

- Run them at your target speed and duty cycle for days, not minutes.

Check:

- Noise, vibration, heat during continuous operation

- Real repeatability with payload

- Any alignment sensitivity or troubleshooting linear actuator quirks during homing and limit sensing

8.2 Pilot batch before full rollout

Before volume orders:

- Run a pilot batch (say 20–50 units)

- Apply incoming QC on critical dimensions and motion feel

- Install a subset in machines for each key industry use case:

- A linear module for 3C electronics station

- A linear actuator for battery production line cell

- A linear module for semiconductor equipment or linear actuator for medical device automation demo