Why 3C Electronics Lines Prefer Fully-Enclosed Ball Screw Modules

2025-12-18Motion Platforms for Lithium Battery Production: Coating, Stacking and Formation

2025-12-221. Why PV and Energy Storage Are Different from “Normal” Automation

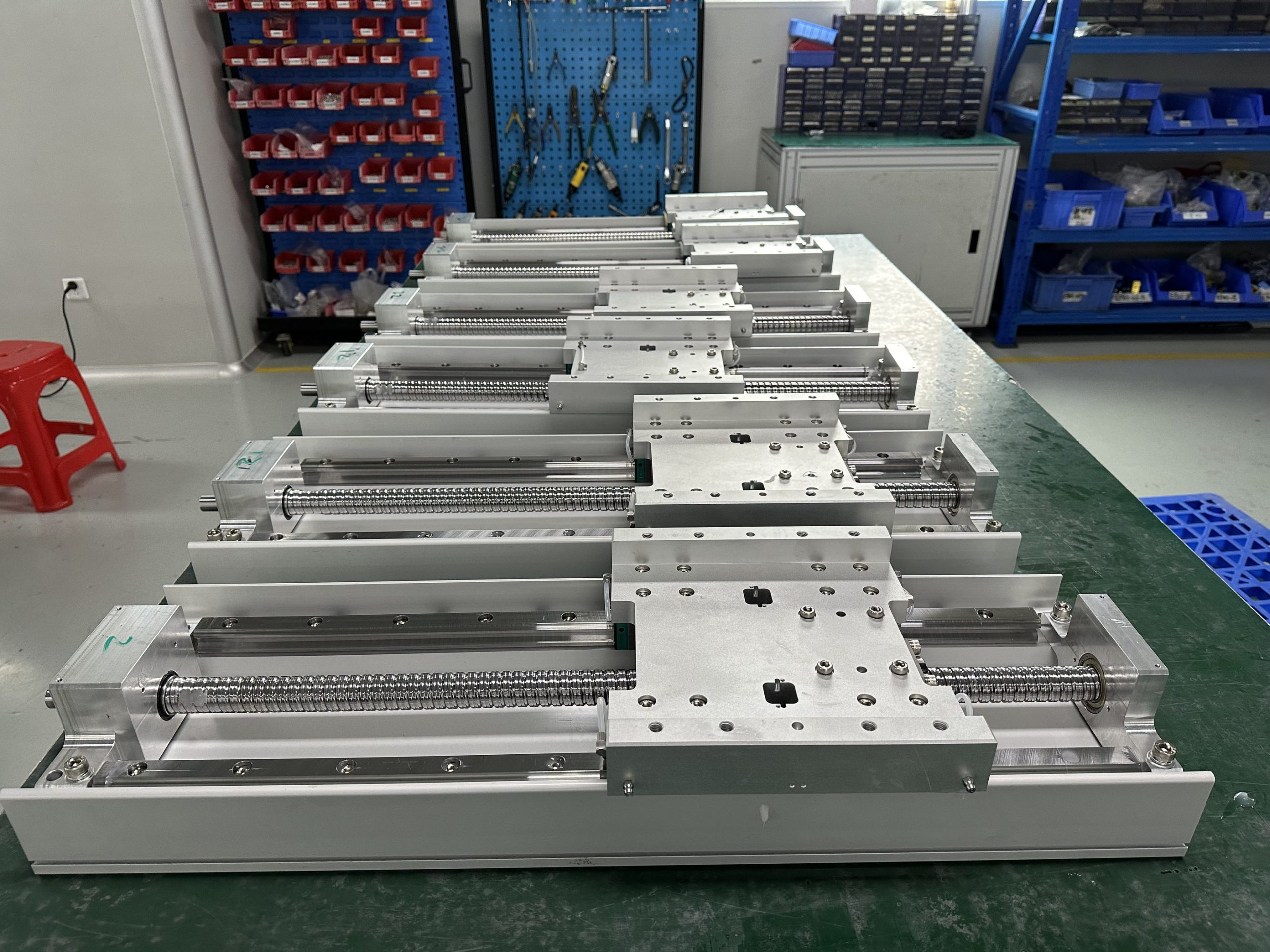

A linear module for automation in a 3C factory moves small products over short strokes in relatively clean conditions.

On a PV or energy storage line, the same-looking axis is expected to:

- Move 20–40 kg glass panels or battery trays over 1–3 m stroke length

- Survive glass powder, cutting dust, slurry mist, or insulation debris

- Accelerate and decelerate big inertia loads thousands of times per shift

- Work on gantries above people and expensive equipment

For your pain points, that translates to:

- Engineers worrying about deflection, accuracy and emergency stopping of heavy payloads

- Purchasers being pushed to buy cheaper axes, only to pay later in downtime and broken glass

- Factory owners seeing OEE drop because “axes need adjustment again”

Designing axes for this world is a different ball game.

2. Long Stroke + Heavy Glass = Structural and Drive Challenges

2.1 Stroke length drives everything

A 2.5 m stroke is not just “a bit longer” than 600 mm. It changes:

- Critical speed for a ball screw drive (risk of whipping)

- Deflection of the extrusion under glass-panel weight

- Requirements for lm guide / linear guide rail size and spacing

For long strokes with heavy loads, you usually end up with one of these patterns:

- Timing belt drive for fast, long transfer axes

- Ball screw drive for shorter precision axes (clamping, alignment, Z)

- Occasionally linear motor for special high-speed shuttles

If you try to push a thin 20 mm screw to 2.5 m with a 30 kg panel on top, you’re basically building a bow and arrow.

2.2 Heavy panels + inertia

PV and storage modules don’t like sudden stops.

Your axis must handle:

- High inertia from glass + frame + tooling

- Shock loads if panels are misloaded or slip

- Torsion if a panel is not perfectly centered

That’s where properly sized lm guides, support bearings, and couplings matter just as much as the drive itself. Under-dimensioned rails may look fine in CAD, then develop play and vibration in months.

3. Drive Choices: Ball Screw vs Timing Belt vs Linear Motor

3.1 Ball screw drive – for short, precise segments

Use a ball screw drive where you need:

- Short/medium stroke precision (e.g. 300–800 mm)

- Tight control of alignment or pressing force

- Vertical Z axes or clamping units

Examples on PV / ESS lines:

- Positioning glass for edge grinding or laser scribing

- Precise lifting of panels with an electric cylinder

- Small linear actuator for pick and place units feeding a bigger gantry

Pros: high stiffness, predictable backlash, good with servo motor linear module control.

Cons: limited speed on long strokes; not ideal as the main panel-transfer axis.

3.2 Timing belt drive – the workhorse for long strokes

For long strokes and high speed, a timing belt drive module is usually the main X axis:

- 1–3 m stroke length without screw whipping

- Lower moving mass than a long screw

- Good fit for multi-axis linear actuator gantries over PV strings or laminators

You can then put a shorter ball screw drive module on top for fine positioning. This kind of stacked 2-axis gantry stage or 3-axis linear motion system is very common in PV glass loading and battery module transfer.

3.3 Linear motor vs ball screw in PV / ESS

Linear motor vs ball screw is a legit question in some high-end lines (e.g. ultra-fast tabbing/ stringing). But in many PV and storage plants:

- Floor conditions, dust and budget often favor robust screw/belt systems

- Linear motors demand very stiff frames and clean conditions to shine

Use them selectively – not just because they look cool in a brochure.

4. Dust, Glass Chips and Slurry: Protection Is Not Optional

This is where PV / ESS lines quietly destroy generic catalog modules.

4.1 Dustproof vs fully enclosed vs IP rated

Three typical levels:

- Dustproof linear module

- Simple covers, wipers and seals

- Good for light dust or dry processes

- Fully enclosed linear module

- Screw and lm guide fully covered by metal strips or bellows

- Essential when you have glass chips, EVA scraps, slurry droplets

- IP rated linear actuator

- Specific IP rating (e.g. IP54, IP65)

- For splash zones or near washing / cleaning units

On a linear module for photovoltaic production line, fully enclosed design around stringing, lamination loading and glass transfer isn’t a luxury – it’s survival.

On a linear actuator for battery production line, you may also need protection against powder, binder mist and aggressive cleaning agents.

4.2 Cleanroom linear module? Sometimes, yes

Some energy storage processes (especially final pack assembly and testing) may demand a cleanroom linear module:

- Low particle generation

- Clean lubricants

- Smooth, easy-to-wipe surfaces

You rarely need ISO-class levels on raw panel lines, but you might on cell inspection, module sealing, and high-voltage test equipment.

5. Control Stack: Servo vs Stepper and the Motion Controller

Long, heavy axes expose weaknesses in the control system very quickly.

5.1 Servo motor linear module vs stepper motor linear module

For major PV / ESS axes:

- Servo motor linear module is usually the default

- Handles high inertia better

- Offers better diagnostics and smoother motion

- Stepper motor linear module may still be fine for auxiliary tasks

- Small gates, stoppers, labelers, simple linear module for automation functions

On large gantries, pairing a robust mechanical design with a good motion controller is more important than squeezing a bit off servo linear actuator cost.

5.2 Integrated motor and driver

For distributed systems or modular stations, an integrated motor and driver on smaller axes can:

- Reduce cabinet space

- Simplify wiring

- Make OEM panels cleaner

But on long, heavy main axes, standard servos plus dedicated drives often remain the safer choice.

6. What Purchasers and Owners Should Ask Suppliers

Here’s where your pain points as procurement or factory owner meet engineering reality.

When you talk to a linear actuator supplier or linear module factory, don’t just ask for “2 m stroke, 50 kg load”. Ask:

- On mechanics

- How do you size lm guide and linear guide rail for heavy glass panels?

- What’s the recommended maximum speed at our stroke length?

- Can you show deformation data under worst-case loads?

- On protection

- Is this a dustproof linear module or a fully enclosed linear module?

- What is the sealing concept around the screw and guides?

- Do you have options for IP rated linear actuators near wet/cutting zones?

- On applications

- What references do you have as a linear module for photovoltaic production line or linear actuator for battery production line?

- Can you provide a custom linear actuator or OEM linear module variant if we standardize on one platform?

- On lifecycle and cost

- What’s the expected life in cycles at our load, speed and environment?

- How do you support troubleshooting linear actuator issues in the field?

- How does your higher linear module price translate into fewer stoppages or lower spare parts consumption?

The suppliers that answer these questions clearly are the ones that will save you money after commissioning, not just on the PO.

7. Conclusion & CTA: Design for Reality, Not for the Catalog

PV and energy storage plants are tough on motion hardware:

- Long strokes

- Heavy glass and steel

- Dust, chips, slurry and frequent cleaning

The safest path is to build your key axes around:

- The right drive architecture (timing belt drive for long strokes, ball screw drive for precise segments)

- Properly sized lm guides, structure and support bearings

- A fully enclosed linear module or at least robust dust protection

- Servo-based control tuned for heavy, long axes