Linear Modules for PV and Energy Storage Lines: Long Stroke, Dust and Heavy Glass

2025-12-197 Reasons Medical Automation Pushes Linear Modules to Their Limits

2025-12-231. Why Motion Platforms Decide More Than You Think

In a lithium battery plant, motion platforms don’t just “move things”. They set the ceiling for:

- Coating thickness stability

- Stack alignment and dimensional consistency

- Smooth, damage-free handling of heavy trays in formation

In other words, they heavily influence:

- Engineers’ pain – endless tuning, compensations and “mystery” misalignments

- Purchasers’ pain – systems that look cheap on paper but cost a fortune in maintenance

- Owners’ pain – beautiful PowerPoint OEE that never appears on the real dashboard

Good chemistry with bad motion platforms is a slow disaster. So let’s break it down by process.

2. Coating: Long Stroke, Constant Speed, Tight Coordination

In coating, your goal is not just “move web from A to B”. It’s:

- Long stroke with very stable speed

- Tight coordination with tension control and dryer temperature

- Smooth motion to avoid thickness ripple and edge defects

2.1 Typical motion platform architecture

Around the coater you’ll usually find:

- A long-stroke linear actuator for battery production line handling web transport and correction

- Short-stroke, high-precision axes adjusting die head position and gaps

- An XYZ linear module platform carrying cameras or lasers for edge and thickness inspection

Mechanically, a common pattern is:

- Main transport axis:

- Timing belt drive with robust lm guide / linear guide rail

- Stroke length in the 1–3 m range

- Designed for smooth velocity and controlled inertia rather than microns of positioning

- Trim/adjust axes:

- Ball screw drive based linear module for automation

- Paired with a servo motor linear module for fine control in the μm range

A capable motion controller then synchronizes web movement, die head adjustments, and inspection triggers so the whole system behaves like one coordinated machine.

2.2 What this means for buyers and owners

- For purchasing: this is why “just a conveyor” is not a fair comparison. The main coating axis is a precision motion platform, not a generic roller table.

- For owners: a line that looks similar in layout can behave very differently in production, because the underlying motion design is not the same.

Material transfer platform

3. Stacking / Winding: Precision Assembly on Moving Axes

Stacking and winding look like pure mechanics from the outside. In reality, they’re closer to precision assembly:

- Alignment tolerances often in the ±0.05–0.10 mm range

- Multiple axes inserting, pressing, and releasing in tight coordination

- Any dust or misalignment directly impacting internal short risk and energy density

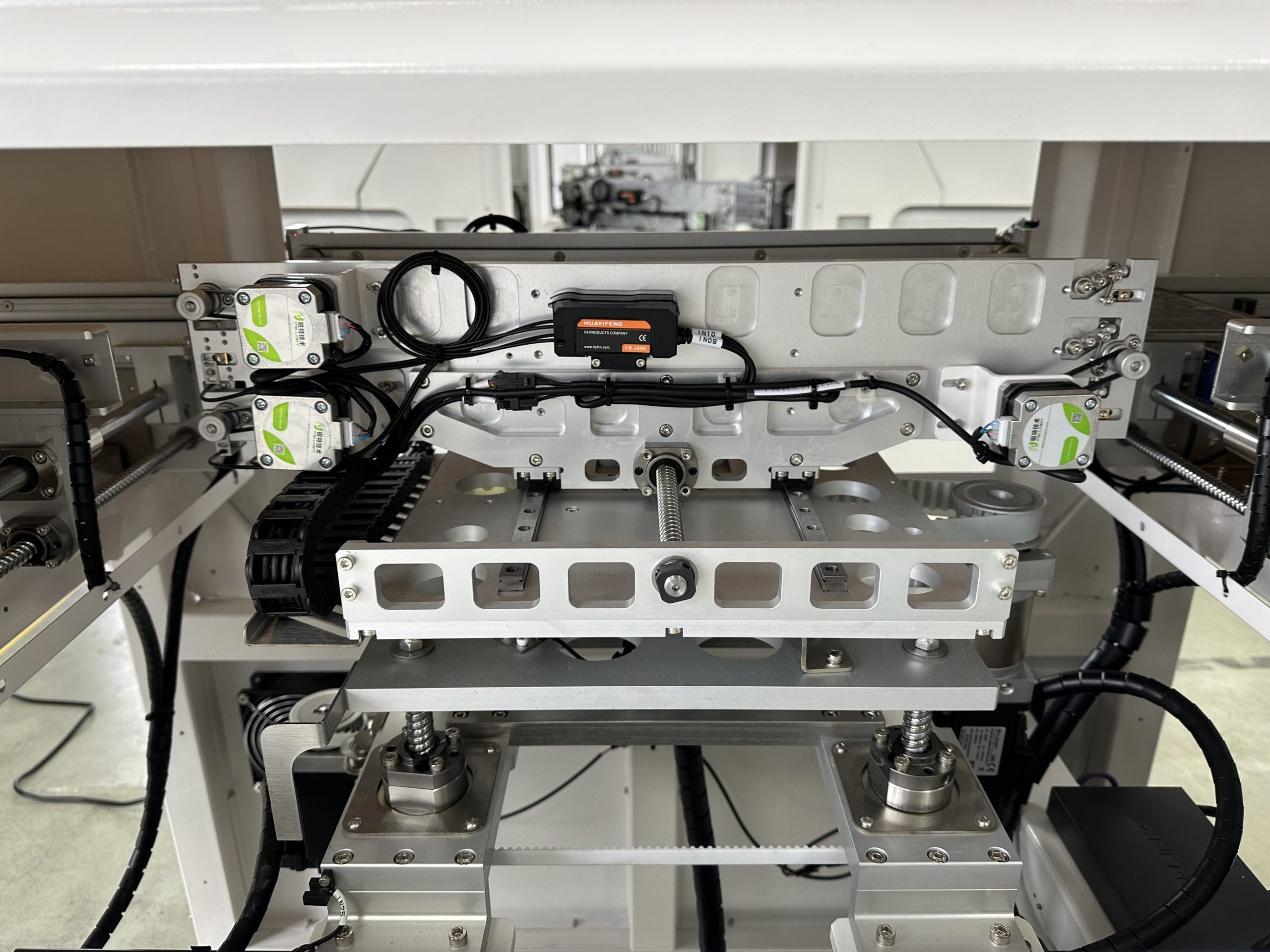

3.1 Motion platforms inside a stacking machine

A typical stacking or winding head might use:

- XY axes built from ball screw drive modules with wide linear guide rails, forming a stiff planar platform

- A Z axis using a servo motor linear module or electric cylinder with brake for safe vertical motion

- A robot gripper or vacuum tooling mounted to a compact multi-axis linear actuator assembly

Together, these axes become a tight, repeatable XYZ linear module platform integrated into the stacking frame.

3.2 Why not “just belts and steppers”?

In this part of the line:

- Repeatability and stiffness matter more than headline top speed

- Coordinated moves across several axes demand a capable motion controller

- A mis-sized or flexible axis shows up as skewed stacks, tilted cells, and long debug cycles

There is still room for stepper motor linear module solutions – for example on auxiliary axes with looser tolerances. But for core stacking motions, cutting corners on mechanics usually comes back as scrap and downtime.

4. Formation: Slow Motion, Heavy Loads, Long Life

Formation and aging don’t look dynamic. Racks move slowly; everything appears relaxed. But the demands on motion platforms are still serious:

- Racks and trays can weigh tens or hundreds of kilograms

- The system must run for years, not months

- Any jam or impact can damage tabs, welds, or cases

4.1 Motion platforms in the formation area

You’ll typically see:

- Long-stroke linear actuators for battery production line moving heavy trays into and out of banks

- Gantries or lifters using heavy-duty multi-axis linear actuators for stacking/unstacking

- Smaller linear modules for automation doing barcode reading, vision checks, label placement, or EOL inspection

Here, the focus shifts to:

- Robust mechanics and materials

- Protection level: dustproof linear module or even IP rated linear actuator where there is vapour, dust, or aggressive cleaning

- Maintenance: access to lubrication points, clear intervals, spare-part strategy with your linear module manufacturer

Formation motion doesn’t need nanometer precision, but it does demand reliability, safe handling of heavy loads, and predictable lifetime.

5. Turning This Into a Practical Selection Workflow

Whether you’re in engineering or purchasing, you can turn all of this into three simple steps.

Step 1 – Classify axes by process

Group axes by what they actually do:

- Coating – long stroke + constant speed

- Focus on timing belt drive, structural stiffness, and speed stability

- Stacking / winding – high precision + stiffness

- Focus on ball screw drive, rail size, and multi-axis coordination

- Formation – heavy load + long service life

- Focus on IP rated linear actuator, sealing, durability, and maintenance

This quickly shows which axes can use simpler solutions and which truly need premium motion platforms.

Step 2 – Write a one-line “duty sentence” for each critical axis

Examples:

“Move 25 kg tray over 2.2 m in 3 s, 24/7, dusty environment, ±0.5 mm repeatability.”

“Move 3 kg end-effector over 400 × 250 mm in 0.8 s, ±0.05 mm, clean environment, close to stacking head.”

These sentences are gold when you talk to any linear actuator supplier.

Step 3 – Challenge your suppliers with the right questions

For each duty sentence, ask:

- Which architecture do you recommend: ball screw drive or timing belt drive, and why?

- How would you build a multi-axis linear actuator or XYZ linear module platform for this duty?

- What lifetime, lubrication interval, and typical troubleshooting linear actuator issues should we expect in this environment?

Good suppliers will respond with a coherent motion platform concept. Others will just throw catalog part numbers and prices at you.