W-Robot VETH Series: Where Precision Meets Power

2025-11-08Shenzhen Willobot Robot Co., Ltd.

2025-11-111. Introduction: The Rise of Smart Gripping Technology

In the age of intelligent manufacturing, the evolution of automation has brought about a new demand — not just for faster machines, but for smarter and more precise manipulators. Among the many innovations driving this transformation, electric grippers have emerged as one of the most crucial components enabling flexible, intelligent, and efficient robotic operations.

W-ROBOT, a global leader in linear motion and automation technology, is setting new benchmarks in this field with its comprehensive range of Electric Grippers. Designed to meet the challenges of modern industrial automation, W-ROBOT grippers combine precision control, compact design, and intelligent sensing, making them ideal for both traditional manufacturing and cutting-edge collaborative robotics.

2. Product Overview: Precision Meets Intelligence

The W-ROBOT Electric Gripper Series includes various models such as the EPG, EPGC, EPGS, and ERG types, each engineered to address specific automation requirements.

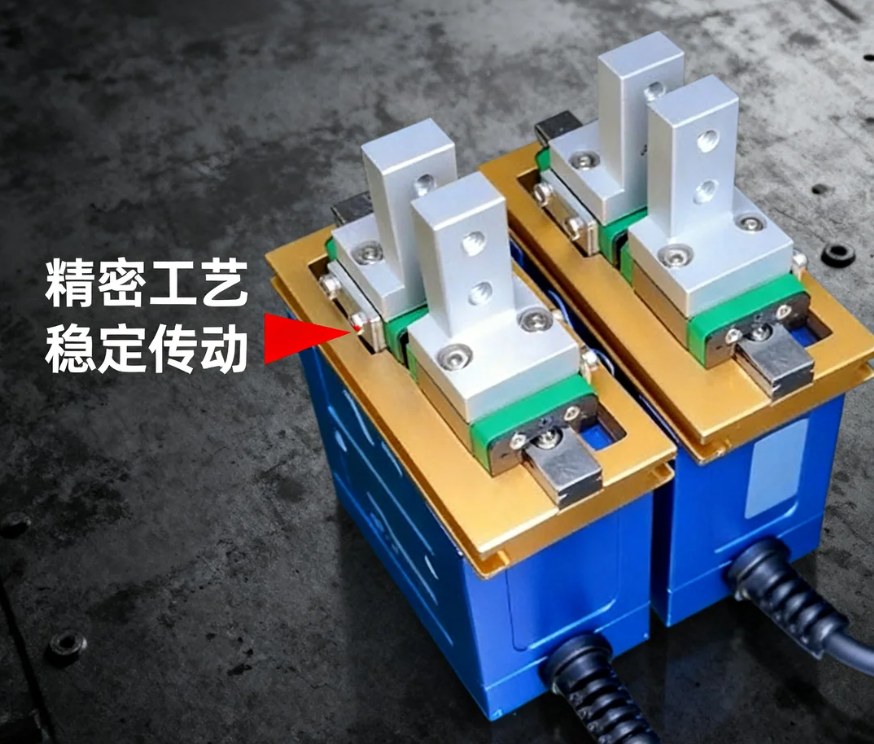

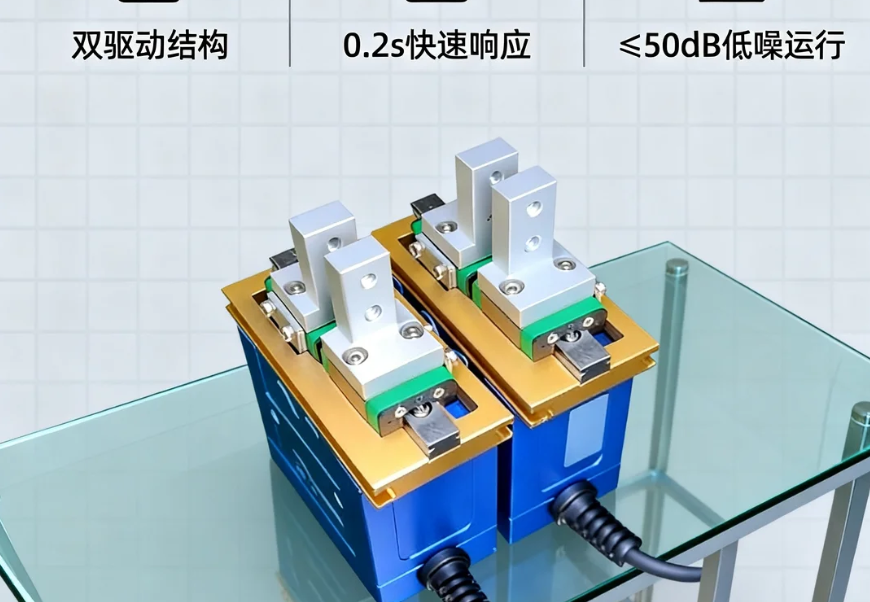

These grippers utilize advanced servo control systems and closed-loop feedback technology to achieve micron-level positioning accuracy. Compared to traditional pneumatic grippers, electric grippers deliver smoother motion, adjustable gripping force, and real-time feedback, allowing users to achieve both gentle handling and high-strength clamping in a single device.

The combination of speed, precision, and flexibility makes W-ROBOT’s electric grippers suitable for a wide range of applications — from semiconductor handling to medical device assembly and electronic product packaging.

3. Key Technical Features

Closed-loop servo control system for high positioning accuracy and stability

Adjustable gripping force and stroke for flexible handling of various materials

Compact and lightweight design, ideal for integration with robotic arms

Built-in sensors for position, force, and status monitoring

Plug-and-play communication with mainstream robot controllers (EtherCAT, Modbus, CANopen, etc.)

Low noise and energy efficiency, ensuring a cleaner and more sustainable production environment

High repeatability, achieving consistent precision even in long-term operation

Each product series within W-ROBOT’s electric gripper portfolio offers unique characteristics:

The EPG Series focuses on high precision closed-loop control.

The EPGC Series provides large stroke and strong gripping force for heavy-duty tasks.

The EPGS Series represents economic models that balance performance and affordability.

The ERG Series combines rotation and clamping in a dual-axis servo system, enabling more complex manipulation.

4. Application Fields

The versatility of W-ROBOT electric grippers allows them to be widely applied in:

Semiconductor and electronics manufacturing – for chip placement, wafer handling, and PCB assembly

Automotive industry – for component gripping, inspection, and assembly automation

Pharmaceutical and medical equipment – for precision assembly and packaging of delicate instruments

Logistics and 3C automation – for fast and accurate pick-and-place operations

Collaborative robots (cobots) – providing intelligent gripping solutions for flexible automation environments

Whether in a high-speed production line or a delicate lab environment, W-ROBOT electric grippers deliver consistent performance and unmatched precision.

5. Advantages of Choosing W-ROBOT

As a direct manufacturer and innovator, W-ROBOT holds several competitive advantages:

Source Factory Advantage – In-house R&D and production ensure cost control, fast delivery, and customization flexibility.

Full Motion Product Line – From linear actuators, motorized stages, electric cylinders, to grippers, W-ROBOT provides complete motion control solutions.

Customization Capability – Tailor-made solutions for specific industries, including adjustable stroke, load capacity, and communication protocols.

Proven Reliability – Products undergo rigorous quality testing, ensuring long service life and stability.

Global Service Network – Technical support and distributors across Asia, Europe, and America provide localized service and fast response.

W-ROBOT’s strength lies not only in its products but also in its engineering depth and long-term partnership approach, helping customers build smarter, faster, and more flexible automation systems.

6. Model Selection & Customization

W-ROBOT offers flexible customization options across its gripper series:

Adjustable stroke and force range to fit delicate or robust gripping needs

Multiple communication interfaces for seamless robot integration

Optional sensors and feedback systems for precision monitoring

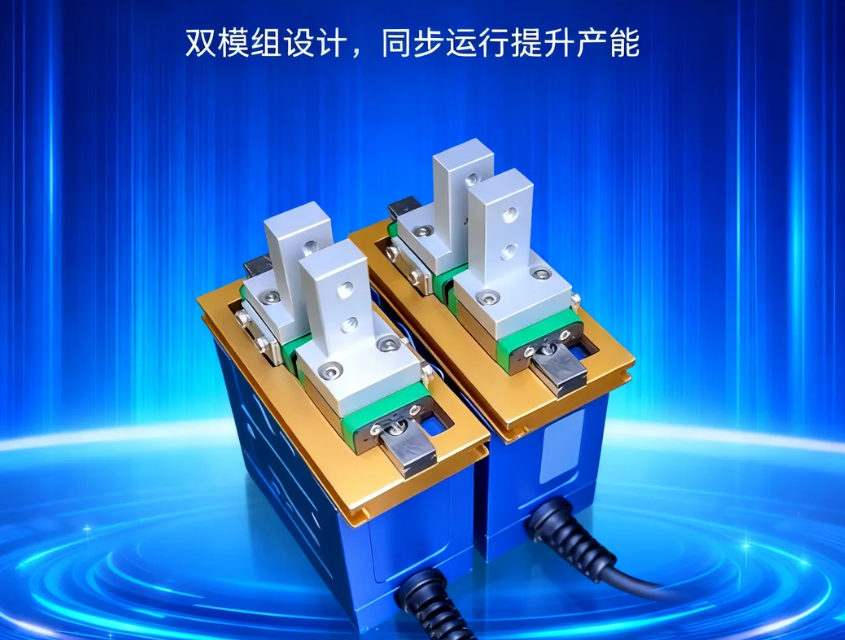

Support for dual or multi-axis synchronization

Custom mounting and housing designs to suit special equipment layouts

By leveraging modular design and standardized components, W-ROBOT ensures rapid prototyping and scalable production, making customization efficient and reliable.

7. Installation & Maintenance

To ensure optimal performance, W-ROBOT recommends the following installation and maintenance guidelines:

Verify flatness and rigidity of the mounting surface before installation

Keep the gripper and moving components clean and dust-free

Regularly inspect connector torque and ensure all cables are properly fixed

Avoid operation in high-humidity or magnetic environments

Perform system calibration every six months for best accuracy

Use original spare parts for maintenance to preserve warranty and reliability

These practices guarantee consistent operation and extend the product lifespan, ensuring stable long-term performance.

8. W-ROBOT: Driving the Future of Automation

With over a decade of expertise in motion control and intelligent automation, W-ROBOT continues to lead innovation in linear actuators, electric grippers, and robotic motion systems.

From design to manufacturing, every detail reflects precision, stability, and intelligence.

Whether you are building a new generation of smart robots, semiconductor equipment, or automated inspection systems, W-ROBOT offers the perfect motion solution tailored to your needs.

For more details, visit the official website: www.w-robot.com

or contact the technical support team for model selection and engineering consultation.